Stay up to date on the Latest Industry News with our Blogs

A Quick User and Glossary Guide to FIBC Bulk Bags

A Quick User and Glossary Guide to FIBC Bulk Bags

F.I.B.C Bulk Bags, also known as flexible intermediate bulk containers (FIBCs) and also known as ‘Dumpy Big Bags, are manufactured to precise standards and can be classified as either multi-trip or single trip. Single-trip bags have a safety rating of 5:1 which means the bag is designed to withstand five times the safe working load before failure. Nonetheless, bags must never be filled above the safe working load. By comparison, multi-trip bags are design to a safety rating of 6:1 – this added resilience is necessary to deal with the repeated use and the stresses of cyclical loading.

FIBC's offer many advantages, mostly their affordability, versatility, durability, and ease of use. One other notable huge advantage is their ability to be easily moved, picked up by grab lorries, forklift trucks, and easily loaded onto transport lorries for shipping by Hauliers, Vans, and Tipper Trucks, etc.

They can be stacked (depending on contents and wrapped easily and perfect to be used on pallets, this is one of the reasons they have risen to high popularity over recent years for such a wide variety of industrial and DIY applications.

When transporting and shipping Dumpy Bags, it is important to know the best practices for Safe Stacking and Securing them. Other factors you should be considered. Let’s explore the best practices for transporting and shipping FIBC Bulk Bags.

Use-ability:

Free Stacking: The free stacking method is popular and involves simply placing one FIBC bag on top of another this is useful with building materials such as gravel, sand, ballast and firewood logs for log burners.

Always ensure your Bulk Bags are Fee Stacking safely and take care to lower each bulk bag slowly. Pressure can be applied to the bottom bags to act as a stable foundation for Free Stacking and subsequently added to the top of the stack helps.

Free stacking is a convenient and practical method to use when the materials contained within the Bulk Bag can withstand the weight of bags stacked atop them.

Pyramid stacking: The Pyramid stacking method is that's also popular and is just what it sounds like – Stacking Bulk Bags in a Pyramid type structure ensure extra safety consisting of large Bulk Bags at the bottom of the Pyramid stack and smaller or fewer bulk bags places at the top. Pyramid stacking is a preferred method for many applications from Industrial applications to Waste and DIY requirements.

Supported stacking: This is another popular preferred method for mainly for transportation and shipping applications as Bulk Bags are supported from Stacking. This involves placing stacked bags in even rows against a wall, rigid containers, such as the wall of a truck or trailer, and supported by Straps. Supported stacking helps to limit material shifting during transit, transportation.

It is important when choosing a method of stacking Bulk Bags (Dumpy 1 Tonne Sacks) Bags for transportation or shipping, always carefully consider all factors and select the method that offers you optimal protection and safety for the materials inside each bag whilst ensuring maximum safety for all personnel operating the Bags are who are involved in both ends of the process.

Palletising FIBCs Bulk Bags:

It is important to note that while stacking Bulk Bags Bags for transporting is a sound strategy, it isn’t always a viable or the best option, especially when putting larger quantities of Bulk Bags into a single Van, Truck or Grab Lorry.

When stacking Bulk Bags isn’t an option, you should consider palletizing your Bulk Bags for transportation or shipping. Palletising is a common technique because it provides added security and makes loading and unloading much easier and safer.

Securing FIBC IBC Bulk Bags to Pallets can be tricky, however, there are two effective and economical methods that we see used with great success, including:

The use of Polythene Pallet wrappers. Using pallet wrappers or commonly known as Stretch Film Wrap to secure bags to a pallet is an easy and effective way to prevent shifting during transit and transportation. This method is by far the easiest to secure the Bulk Bag and very affordable.

Strapping Bands: Is another common method of securing FIBC Bulk Bags bags to pallets. This approach creates a strong durable secure load but does involve more labour and can be more expensive than pallet wrapping and plastic wastage can be excessive through the use if Strapping Tape and Tools and components used.

However you choose to secure your bulk bags to pallets, be sure to take the time to do so carefully and securely. Done properly, the palletizing allows for more secure stacking and makes it easier to fit large quantities of bags in semi-trucks for transport. Because FIBC, IBC Bulk Bags are flexible, users can fit many more in a single storage space in the warehouse / storage facility.

Bulk Bags also help you developing the best methods of transporting, shipping and storing your goods inside the bags. Whether you simply need advice or are searching for a new solution for your facility, we can help. In addition to our knowledge of the FIBC, IBC industry, we can also provide pallet machines and stretch wrap supplies perfect for this application through our parent company, Poly Textiles.

-

Below is some common bulk bag / FIBC Glossary Guide for Industry Terminology that you may encounter when choosing the right Bulk Bags

Bulk Bag Specification: An illustration / sketch supplied by the factory in-house for the prospective customer’s approval, The Bag Spec is supplied prior to production, in order to assure compliance with the customer’s needs and expectations.

Baffle Bulk Bag – Pieces of fabric or other material sewn across each corner to form a tubular or four – panel sided bag this improve a bag’s square-ness, appearance, and improve stability and helps the of the load to more effective to utilised for storage or shipping space or transporting.

Bag Height – Height dimension of an FIBC measured from the top Seam to the Bottom Seam. This can sometimes measure from Internal Dimensions or External Dimensions so always worth asking to ensure the size meets your requirements.

Belt Patch A piece of WPP fabric sewn either between the main of the fabric of the bag and the Lift Loops Belt, or on top of the Lift Loops Belt, within the belt that are sewn to portion to ensure, sift resistance and/or the safe working load (SWL).

Tape (Tape Strap, Bias) is from of multifilament yarns, (MFY), polyester or woven polypropylene, and used to tie inlet and outlet spouts. And used as a Draw Cord. Also called a Web Tie or Tie Strap Cord.

What is Body Fabric The Body Fabric is the Main Fabric of the Bag and used usually used on the body of a U-panel, Four Panels or Circular and Tubular Bulk Bag.

Bottom Fabric is the bottom material of a tubular or four panel body fabric on the Bulk Bag.

Bottom Spout also called also called a bottom Discharge Spout, this is useful and used as an Outlet to help empty the contents of the FIBC IBC Bag and helps to eliminate wastage when emptying contents inside the Bag..

Breathable Fabric Fabric Uncoated or Non-Laminated fabric / Bulk Bags, These are available in various Fabric made from WPP such Mosquito Netting or Vented with Vertical Stripes on all sides or double sides making the Bag useful for Storage of Dried Logs and Kindlin and helps to eliminate Moisture if stored outside, Garages, Sheds, Open Barns and Front Garden Porches.

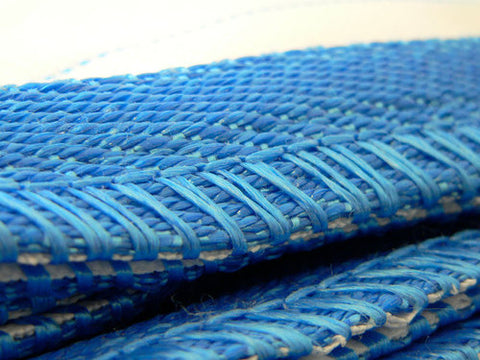

Circular Woven Bulk Bag are also known as tubular bags, it is made from fabric woven pp on a circular loom using specialist technique during the manufacturing stage of the bag, is then cut to to shape to the proper length to meet the desired specified bag Height and Dimension, thereby eliminating the vertical seams on each of the bag’s sides and making the bags Durable and long lasting..

Cone Top Bag Is a variation known as an inlet, where the top is a shaped as a pyramid to allow over filling of the bag. Is also known as a Conical Top Bulk Bag.

Coated Fabric / Bags – WPP Fabric or bag which is Coated / Laminated with lamination with additional polypropylene (PP) to reduce moisture intrusion and / or sifting of the inside contents to prevent leakage or wastage. This is also known as Non-breathable Bulk Bags, and Laminated fabric applied on the Bulk Bags.

Draw Cord / Lock Rope Cord – A closure device to hold the top, usually a draw / pull cord put in place on the spout by using a Plastic Push and Release button. This typically helps to the discharge the contents of the Bulk Bag with ease.

What is Denier – Denier is the the weight measurement of yarn used in Grams Per 9,000 Metres.

Discharge Spout – See illustration. Also called a Bottom Spouts as mentioned above that's typically used as an outlet to release and empty the contents of the FIBC Bulk Bag.

Document Pouch – Typically made of either polyethylene or polypropylene, it is where shipping or identifying documents are usually placed. Also called a Pocket or Envelope. This is usually applied whilst bags manufactured at the factory or can be applied after.

Drawstring Closure – A type of spout construction similar in purpose as to a petal closure, but with the loop/string along the circumference of the closure.

Duffel Top – A type of FIBC top similar to a duffel bag whose inlet extends from the top seam and follows the bag’s base dimensions. Also known as a skirt top

Extended Belt – A type of FIBC construction where the webbing extends around the bottom of the FIBC. This construction is not applicable for U-panel FIBC’S.

Fabric Mesh – The measure of the density of the fabric weave, measured as the number of yarns per inch in both the Warp and Weft directions. A typical construction is a 12×12 mesh.

Fabric Weight – The measure of the fabric weight in ounces per square yard or grams per 100 square Centimetres. An example of a fabric weight is 6.5-Oz /Sq. yd.

Fill Spout – Also called an inlet spout or top spout, used as the inlet for filling an FIBC. It is designed to fit the customer’s filling chute during loading.

Filler Cord – Typically a polypropylene material used in manufacturing sift-resistant FIBC’S. A rope or braided yarn-like cord that is sewn into a seam to help prevent the escape of fine dusts and powders.

Form Fitted Liner – Designed to take the exact shape of the FIBC. Form-Fit Liners will allow improved filling and complete discharging of product. Unlike a basic “tube liner”, Form-Fit Liners offer a flat top and bottom and incorporate a spout diameter and length to best compliment the FIBC’S fill and discharge spouts.

Full Open Discharge – A type of discharge whose outlet extends from the bottom seam and follows the bag’s base dimensions. Also called a Full Open Dump.

Hemmed / Hemming – A fold and sew, or glue operation, which prevents fraying of cut fabric and will add lift strength and seam strength to each bag giving you extra durability. This also helps to provide a clean finish to the bag. It may be either towards the inside or outside of the bag. Hemming can be used to achieve desired FIBC dimensions from Body Fabric supplied on Rolls or Sheets.

Lay Flat Width – The width of tubular fabric if stretched or laid flat from edge to edge. A 14” diameter Fill spout would have a lay flat width of 22”.

Loop Height – When layed flat the measurement from top of bag to apex of loop.

Main Fabric – Typically use with U Panel style bag.

M.F.Y Stands for Multi Filament Yarns (M.Y.F) which are used in the weaving of bias tape/straps and lift loop belts. This maybe be constructed of polypropylene or polyester threads.

Multi Trip Use Bulk Bags designed in accordance with ISO 21898 for multiple trips uses.

External Perimeter Belt / Band – Bias tape/strap is sewn around the top seam as a extra reinforcement or used to identifying mark. Also known as Safety Belt.

Petal Closure Spout A four petal like spout is construction and used to hold in the spout during transporting.

Petal Type Bottom Spout A type of petal closure that is separate from the bottom fabric and used to hold in and protect in conjunction with the spout during transporting. This is also referred to as reinforcement bottom square.

Polyester A type of polymer often used in producing multifilament and monofilament yarns and weave and threads.

Polypropylene A type of polymer used in producing monofilament and multifilament yams and threads mainly made from virgin Woven Polypropylene on new Bulk Bags.

Port Hole A type of outlet constructed without a spout. The hole cut is reinforced with tape / or strap.

Reinforced Sectioning Section of the FIBC Bulk Bag where the lifting Loops Belt are sewn onto the fabric. This section of fabric has additional Warp yarns stitched helps to contributes to the strength of the bag.

Remote Open Discharge A type of special outlet that has provisions for discharge of material without an operator reaching under the bag to open the spouts to avoid accidents by the operator using the Bag.

Safe Working Load (S.W.L) is the amount of load, (in pounds or kilograms), which a bag is designed to carry. This is important to ensure the Bulk Bag can accommodate the weight. Most common Bulk Bags have a SWL of 1,000kgs however these can increase depending of spec and size of bag.

Safety Factor – This is an industry standard requiring to meet FIBC safety standards to handle five or six times its Safe Working Load, normally calculated as a Ratio 5:1 or 6:1 S.F.

Protective Bottom The bottom diaper that protects the entire bottom surface of the bulk bag for cleanliness. May also be referred to as a protective bottom bulk bag.

Seam – A sew line made by the attachment or assembly of two or more components.

Side Panel A side Panel is the fabric component of a sewn bag and the style of construction. This can be either attached by two pieces and known as U-Panel, or four pieces, which form the Four Panel Sides of the bag.

Sift-Resistant Construction – A type of an FIBC construction that provides resistance from product sifting when the bag is filled with very fine materials. Also referred to as “Sift ¬proof’ construction. This typically utilizes coated fabric and filler cord in the sew lines.

Single Trip Bag – An FIBC designed in accordance with ISO 21898. For one time use.

Spout Cover Top Also called a petal cover, it is a piece of fabric sewn between the spout and the petal closure used to hold in/protect the spout.

Spout Diameter – A dimension of the spout measured across the circular opening, Usually measured in mm's or cm's in diameter

Spout Height Length – Height dimension or length of the spout measured from its point of attachment on the top/bottom fabric to its free end.

Stevedore-Strap It is a belt connecting either two adjacent lift loops, or all four loops, used for single point lifting such as a Fork Lift or Grab Lorry

Stitches per Inch – A sewing specification requiring “X” number of stitches per Sq " Inch.

Top Fabric – The top fabric used on a FIBC.

Tube Liner – A liner with no spouts or contours, it is a straight cylinder, which may or may not have one end heat-sealed.

UV Stabilized – A feature of an FIBC fabric that provides protection from prolonged exposure to the sun’s degrading UV rays. An additive that blended with the resin prior to extrusion of the yarns to provide this protection.

Volume – The size, or amount of material, an FIBC can hold. It is generally measured in Cubic Feet size.

Web Tie – Made of multifilament yarns, polyester or polypropylene and used to tie the inlets and outlets. Also called a Bias Strap, Tape, or Spout Ties.

Yarn/Tape – Extruded PP sheet slit and stretched to form part of the woven fabric for the FIBC.

Self Life of FIBC Bulk Bags Any recommendations in regards to the shelf life of an FIBC, are solely the responsibility of each company. The Flexible Intermediate Bulk Container Body does not endorse or guarantee any typical shelf life.. Variables such as Weather conditions, Ultra Violet (U.V) inhibitor used, Construction quality (fabric and gsm. threading, weight, density, webbing and many other factors need to be taken into account eg, exposure to environmental hazards U.V, extreme temperature change as well as humidity factors when storing, handling / transportation methods and the contents inside of the Bag can dramatically impact the shelf life of of any Bulk Bag. We also recommend the best method for determining if a FIBC remains suitable for use is to regularly conduct periodic performance tests, manual checks e.g. top lift, U.V resistance. Sampling tests also should meet industry standards such as those set forth in ISO 21898 Specification for Bulk Bags. All our Bags are tested during the stage of manufacturing so rest assured our SACKMAN® Bags branded or None branded are made to the highest quality industry standards.

-

We hope you have enjoyed this quick guide and found it helpful, hopefully we hope it has answered some questions that you may of had.

Please Note: This is not a fully comprehensive user guide and If you have any further questions or require a bespoke custom bag solutions please do not hesitate to email our technical team on info@thesackman.co.uk

To Shop Online for Bulk Bags please visit our range on the below link:

> CLICK HERE TO SHOP ONLINE <